![]()

ms Poolzee

The tugboat ms Poolzee (Polar

Sea) - call sign

PGVE - shown in this picture was the third ship by that name. A continuation of a proud Dutch nautical tradition.

The tugs Rode

Zee and Poolzee are sister or

identical ships.

The ms Poolzee was built in 1971 as number

600 by the Dutch Shipyard 'De Merwede' at Hardinxveld.

Gross tonnage: 1321

Propulsion: 2 x 6 cylinder Werkspoor diesel engines type 6TM410 - 11.000 Hp (5.148 kW). One screw with nozzle and twin rudders. See picture and explanation below of the advantages of such a nozzle.

Speed: 15 knots

Dimensions: LxWxH: 68.51 x 12.60 x 6.40 m

1971 (13th January) ms POOLZEE was delivered to the ship owner L.Smit & Co’s.

Internationale Sleepdienst Maatschappij N.V., Rotterdam.

1972 (10th April) Transferred as ms POOLZEE to Smit Internationale B.V., Rotterdam.

1975 A bow thruster was added at the Shipyard Boele's Scheepswerven en Machinefabriek B.V. at Bolnes.

1984 (July) Renamed to ms 'Smit Matsas' and transferred to Smit Matsas (Hellas) Towage & Salvage Ltd. Piraeus.

1985 (13th September) After being hit by an Exocet rocket in the Persian Gulf a fire broke out and the ship was heavily damaged even though the rocket passed through the ship without exploding. The tugs 'Smit Duitsland' and 'Drado' towed the Poolzee to Bahrein.

1986 (January) Arrived at Gadani Beach, Pakistan to be broken up by Murtazvi Enterprised Ltd.

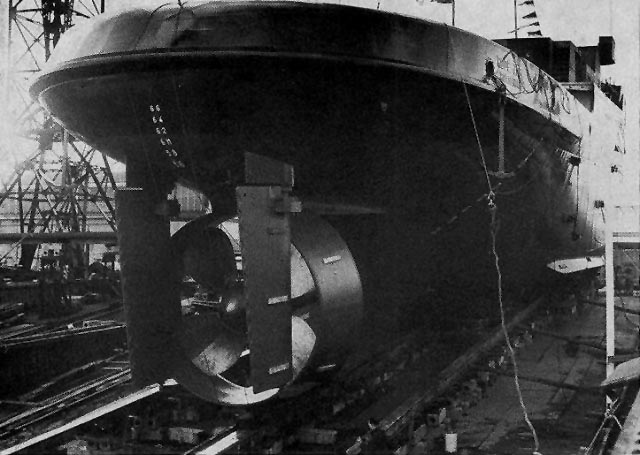

This picture shows the actual nozzle of the

Poolzee. The majority of such nozzles, either fixed or steerable units, are fitted on tugs. The high bollard pulls being demanded by salvage, coastal towage and harbours tugs, makes the fitting of such nozzles essential, for to achieve the same bollard pull with an open propeller requires over 45% more power for the same propeller. The light coloured white metal parts attached to the rudder and nozzle are probably part of the ship's self sacrificing cathodic protection system. This system protects a metal surface of corrosion. Because of the copper screw near the steel nozzle and rudders corrosion especially in this area can be dramatic.

A cross section of the nozzle has, in effect, the same shape as an aeroplane's wing but instead of 'lift', a forward thrust is produced. There is no increased thrust on the shafting, the extra thrust is passed through into the ship's hull via the nozzle. Another advantage for a tug is that a line cannot easily foul up the ship's screw by accident. Nothing more nightmarish for a tugboat's crew than to be run over by the towed vessel or object when the screw would get immobilised by such an incident.

Regarding cathodic protection systems it is may be useful to explain the two available systems:

Sacrificial Cathodic Protection: Voltage provided by sacrificial zinc or aluminium anodes is too high when new, causing high stress on new coatings and too low when aging, again causing corrosion as coating deteriorates. Another disadvantage of the sacrificial system is the limited life time, high reinstallation costs, high drag and fuel use. The advantage is the lower purchase costs as compared to the impressed current system where first time investment is relatively high. However, over the life time's span of a ship this system is more cost effective. Also the corrosion control is very superior to that of the sacrificial system.

Impressed Current Cathodic Protection: My company Radio Holland represented and sold the CAPAC impressed current cathodic protection system which is a much more sophisticated way of corrosion protection and all done automatically. This protection is provided at optimum ampere levels - too little and corrosion occurs, too much and coatings may be damaged. With ships, the optimum amount of amperes is always changing. Ampere requirements increase proportionately to ship speed, coating age, and oxygen content. The current provided by the system is automatically and continuously adjusted to meet changing conditions. Life time of the system exceeds 20 years.

CAPAC systems also feature a silver alloy slip band and silver graphite brushes to ensure the propeller and shaft are electrically bonded to the hull. Silver utilised on the contact surfaces provides a low-resistance electrical connection.

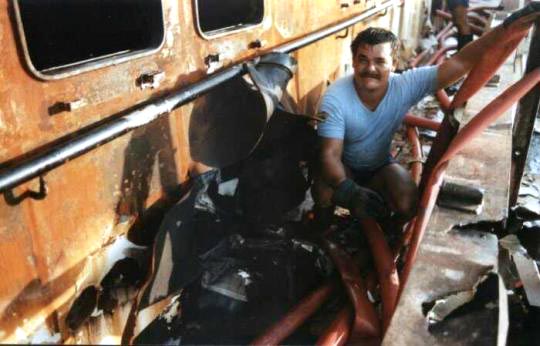

This is what was left of the interior of the 'Smit Matsas' (ex Poolzee) wheelhouse after the fire was extinguished.

The Exocet's missile exit hole is clearly visible. After that it continued it's way right through the bulwark plating.

This is a picture of the predecessor - ms Poolzee (II) - of the Poolzee (III). From the picture above it is clear that the latter is a member of a totally new generation of ocean going tugs.